fastWMS (Warehouse Management System)

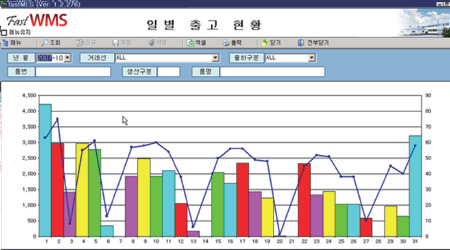

FastWMS is a warehouse and inventory management system based on complex logistics environment and business characteristics. It manages the ordering, goods receipt, order management, picking, warehouse, inventory management, Logistics solution.

Benefit

Inventory accuracy and real-time inventory check management / Load space efficiency and first-in / first-out ability / Effective manpower management by shortening work time from goods receipt to delivery

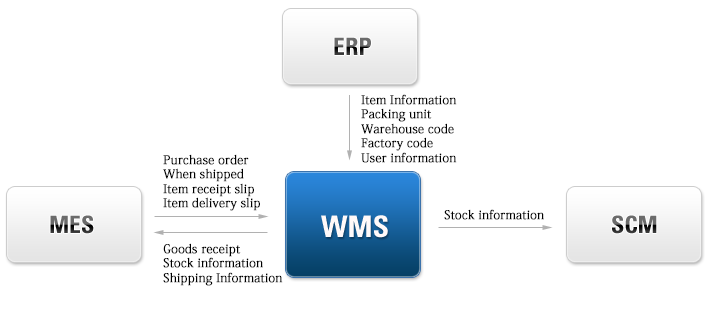

Conceptual diagram

WMS is linked with ERP (Enterprise Resource Planning), MES (Production Management System) and SCM (Supply Chain Management) and receives information for standard information and production from MES / ERP system and executes production and manufacturing activities in a timely manner. And provides accurate inventory information through interlocking with SCM, which enables smooth flow of goods.

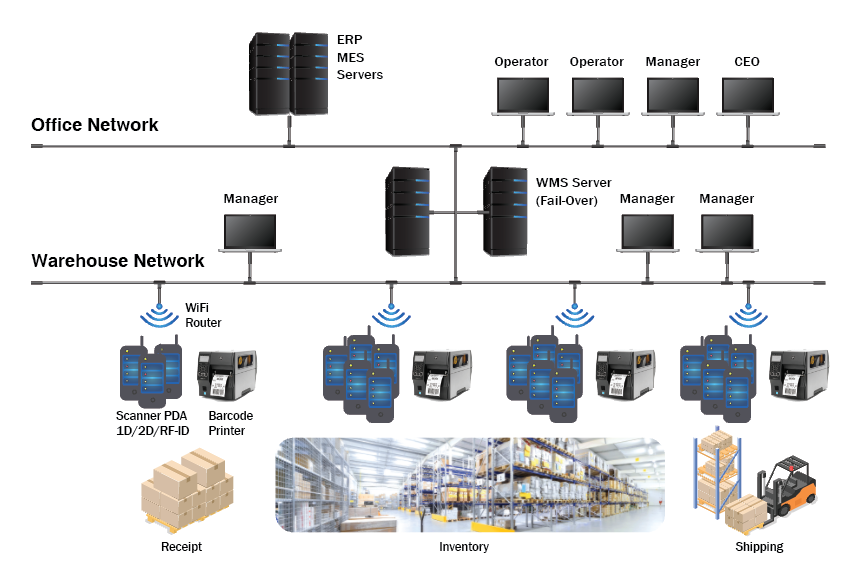

Hardware configuration diagram

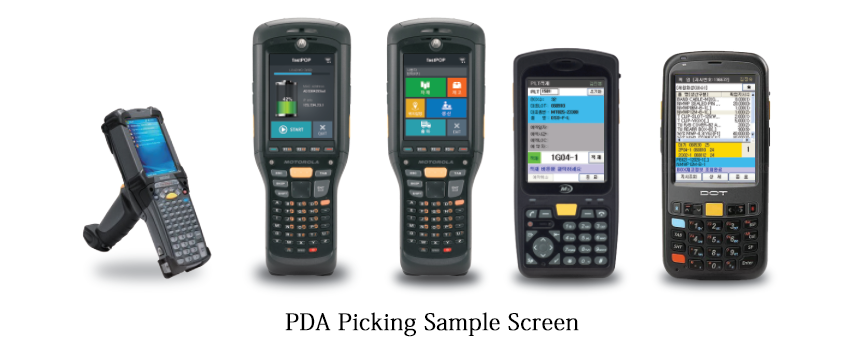

Key Features : Real-time interworking with MES, real-time warehouse status monitoring, data entry, warehousing, picking information verification, barcode issuance and RF-ID data integration

Process

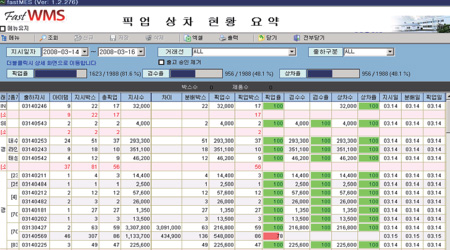

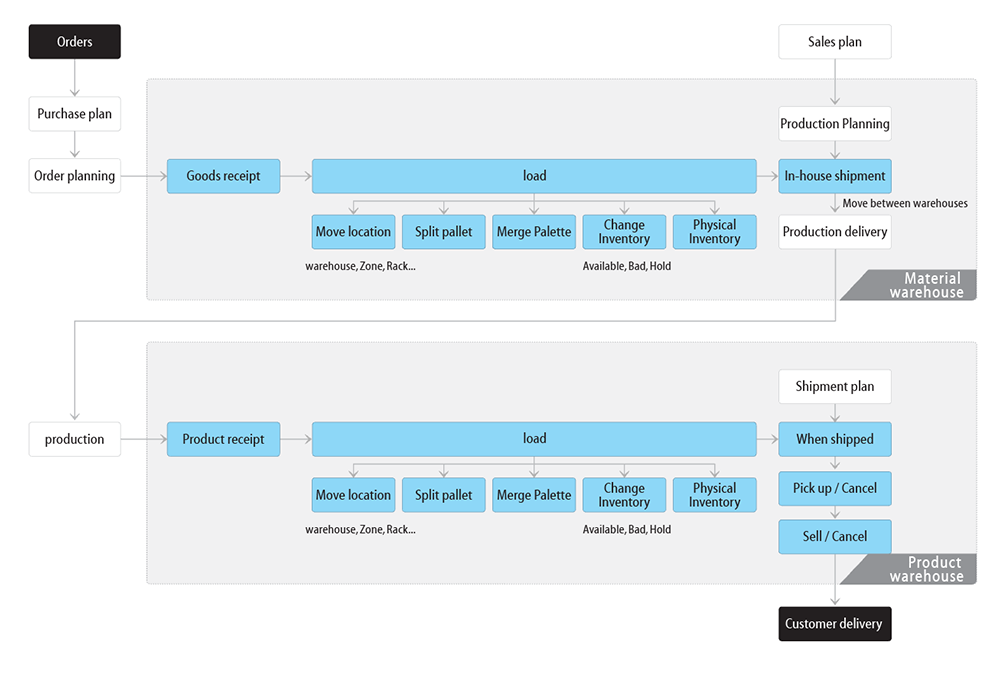

By managing the entry / exit of materials / products according to the linkage with ERP and own production / shipment plan, and managing the loading / moving / picking status in the warehouse, it is possible to grasp the logistics flow in real time

Software Configuration Diagram

It is a WMS professional solution based on experience of building various warehouse logistics management system in Korea. Using proven solutions that are already in use in the field, you can apply them quickly and maximize warehouse operation efficiency.

Base management

- Item code management

- Packing unit management

- Warehouse Code Management

- Factory code management

- User / Operator Management

- System permissions management

- Code Master Management

Goods Receipt

- Purchasing Goods Receipt

- Moving between warehouses

- Stock Status

- Return Status

- Management of the unit cost of goods receipt

Load Management

- Load Location Management

- Pallet configuration

- Dismantling pallet

- Label Issued

- load

- ZONE Management

Inventory management

- Inventory Status

- Inventory Status by Load Position

- Split pallet

- Merge pallet

- Change inventory status

- Label Issued

- Move load location

- Physical Inventory

Shipment management

- In-house shipment

- Factory Management

- Picking

- Picking Status

- Cancel picking

- Selling goods

- Cancel goods issue

- Issuance of waybill / statement

- Goods history

![]()

Main Screen

Effect of introduction

Accuracy of inventory

- Accurate inventory management with real barcode

- Check real-time real-time information by viewing barcode

Real-time inventory check and management

- Real-time location (warehouse, Zone, Rack ...) inventory identification and easy to manage by item and standard

- Providing real-time inventory information to purchasing / sales / shipping business

Efficiency of loading space

- It is possible to reduce the search time and move the inventory by enabling inventory by location

- Efficient management of loading space

First in, first out

- Stock history and real-time barcode attached to the stock at the time of stock

- Decrease risk increase rate of inventory loss due to long-term preservation

- Intelligent racking / picking engine with efficient warehouse operation

Manageability

- Accurate real-time inventory tracking ensures fast decision making

- Improvement of customer's reliability by quick decision making on delivery schedule due to improvement of delivery process

Workforce efficiency

- Efficient workforce management by reducing work time from goods receipt to dispatch

- Beginning worker can also load and pick

- Labor Cost Savings

Free One-Day Consulting

Are you currently reviewing the introduction of a new system or are you having difficulty implementing it? Please tell us without burden and we will contact you shortly.