fastHMI (Human Machine Interface)

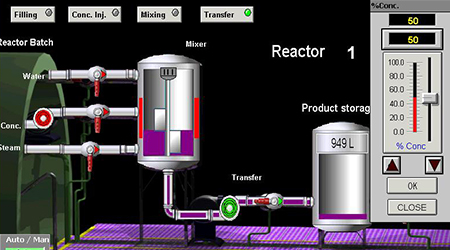

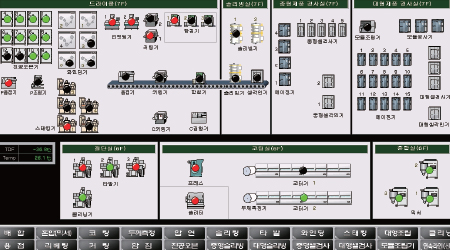

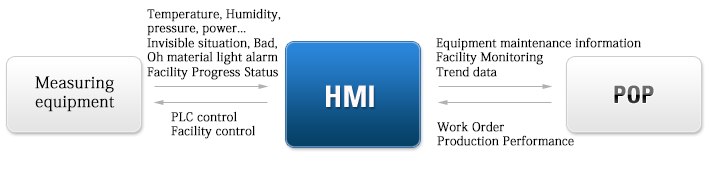

FastHMI combines the functions of HMI and POP (Point of Production) to provide an intuitive and easy-to-understand interface between operators and facilities, and collects, formats, and combines data from various facilities to enable full and detailed equipment monitoring.

Benefit

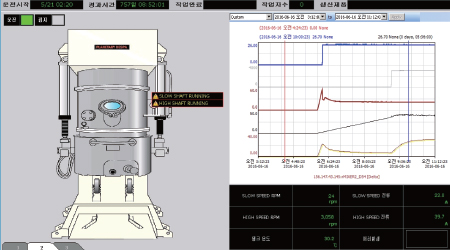

Reduces development and maintenance time by using InTouch, a specialized HMI tool. Provides independent animation for each facility. Displays real-time trend of analog data change.

Conceptual diagram

We collect various kinds of information (production record information, facility operation information, inspection / measurement information, etc.) generated by the facility and work in real time with MES / POP system. Real time control is possible. By providing real-time visibility into the status of processes, you can improve operator efficiency and minimize problems and maximize performance by helping you find and locate unproperated processes and problematic processes

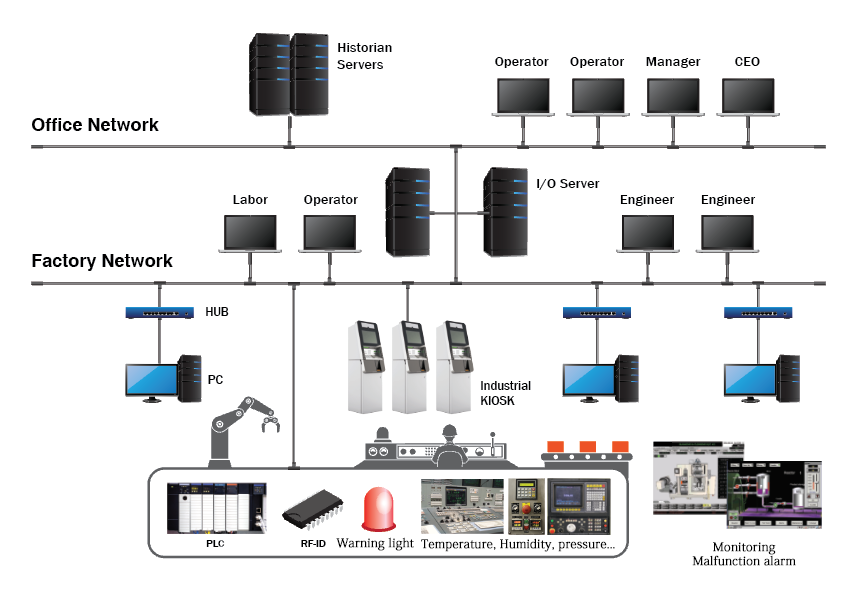

Hardware configuration diagram

Key Features: I / O SERVER Real-time information collection (information from various production facilities, UTILITY, Inspector / Meter) and MES / POP system, real-time monitoring (equipment status, alarm, malfunction alert etc.) Real-time alarm, production / facility condition setting, facility operation control.

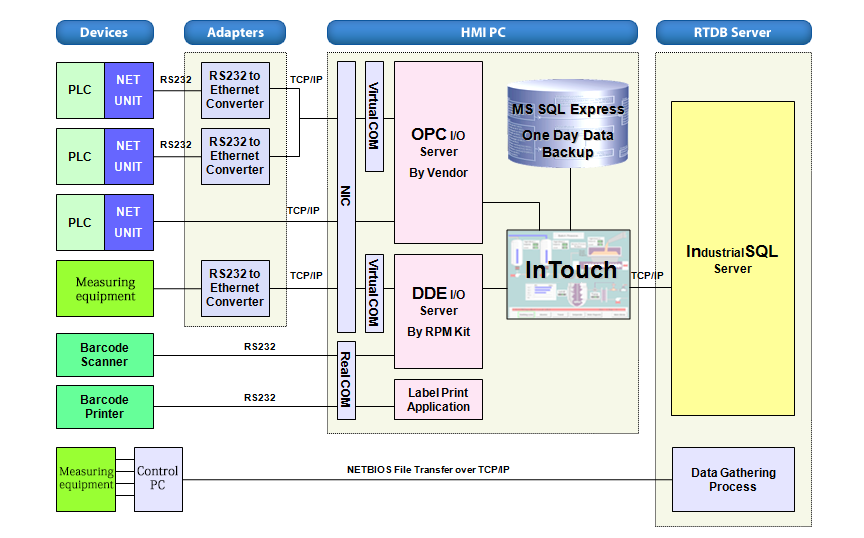

Software Configuration Diagram

Data can be collected by most PLCs through serial communication and Ethernet communication. Data requiring history information is stored in HISTORIAN DB in real time, and it is possible to analyze history and trend of various data in the future. With InTouch, you can visually visualize the interface between operator and system in real time, allowing operators to pinpoint current situations and take action.

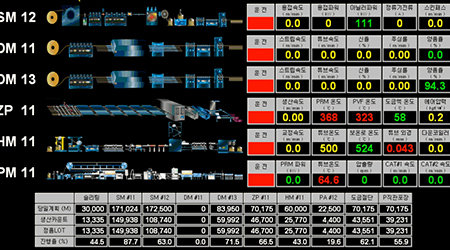

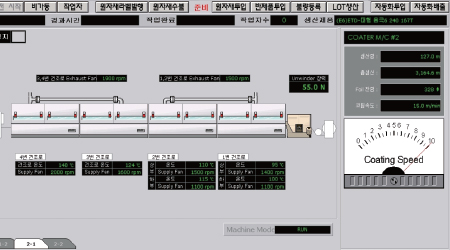

Main Screen

Effect of introduction

Optimal plant condition

- 24 hour facility monitoring control possible

- Alarm can be triggered when abnormal condition is detected.

- Discussion of measures through subsequent analysis with file records of facility status

Operational convenience

- Reduction of risk and maintenance of optimum condition and safety status by standardized management by integrated facility monitoring

- Automatic operation of facilities and colorful user graphic environment

Manageability

- Based on the technology established in the automation system field, considering the advancement of the future technology, it adopts a structure that can supplement or improve the performance by simply expanding the communication network and adding a tag when the load or the load is required. management

Free One-Day Consulting

Are you currently reviewing the introduction of a new system or are you having difficulty implementing it? Please tell us without burden and we will contact you shortly.