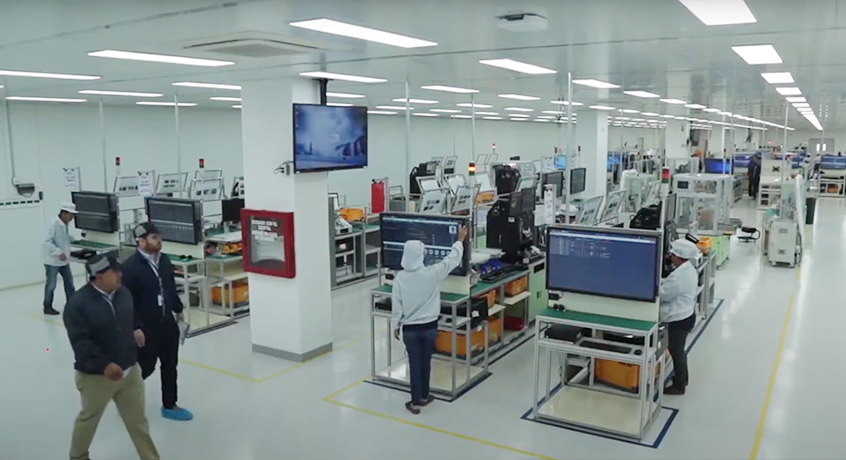

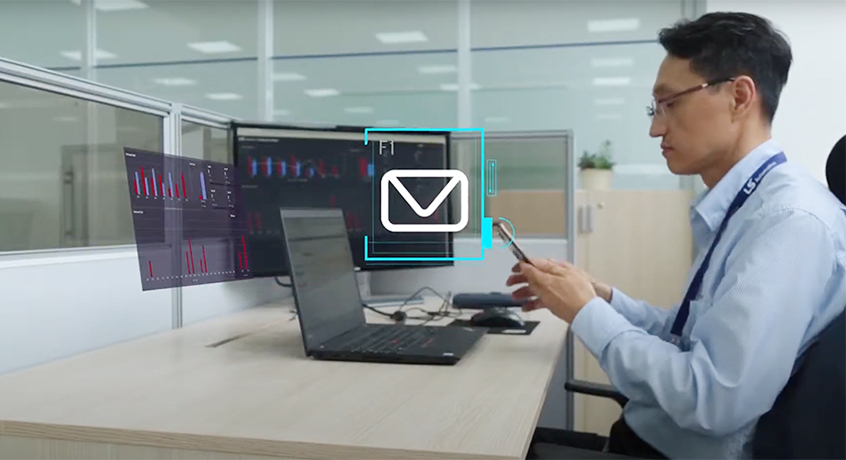

- Customer : Daesung Electric (Qingdao corporation)

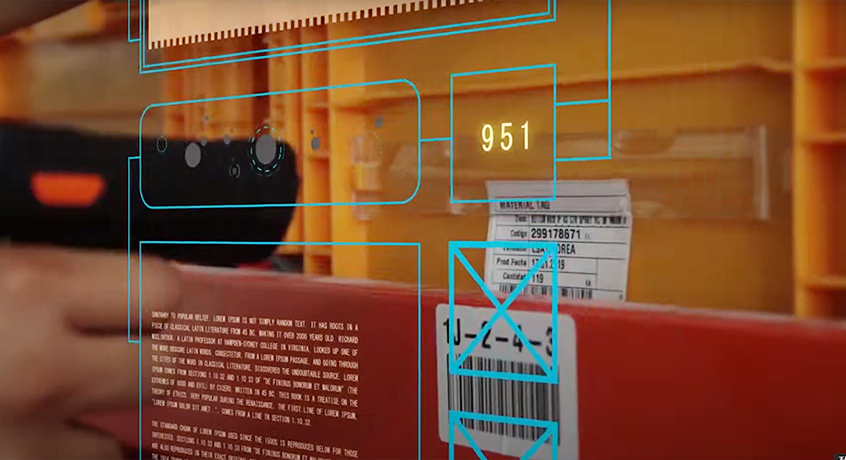

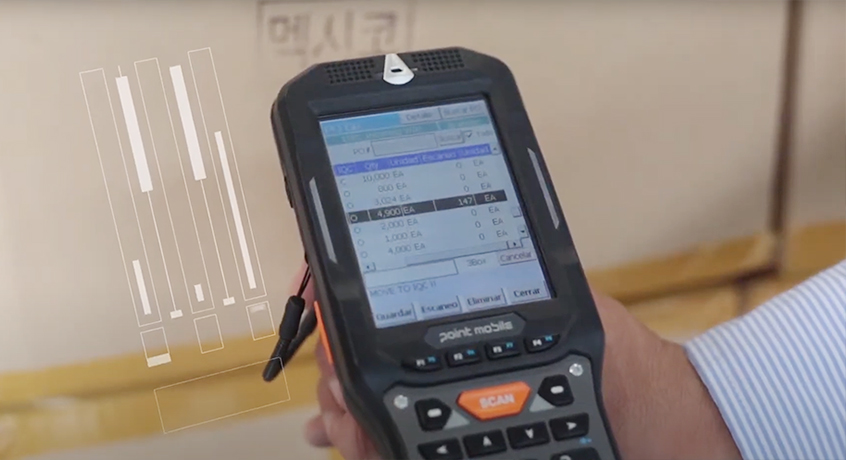

- Project Name : POP System (started in 2012), LOT Tracking System (started in 2014)

Transformed into car parts after LS acquisition / More than 70% automation of injection and assembly / 2008 sales id 50 billion won that last year is 210 billion / Diversify local and global customers in China / Sales will reach 1.5 trillion won by 2020.

Daesung Electric's headquarters in China posted sales of 500 billion Won in 2008 With the development of an advanced manufacturing and management system, quantum jumped more than four times to 210 billion won last year.

When competitors grow 7 ~ 8% per year, Daesung Electric of China corporation maintain high growth of 20 ~ 30% every year.

more