fastMES (Manufacturing Execution System)

fastMES is a manufacturing execution system that ensures production follows the plan and aids quick decision-making by collecting and analyzing valuable on-site data.

Benefit

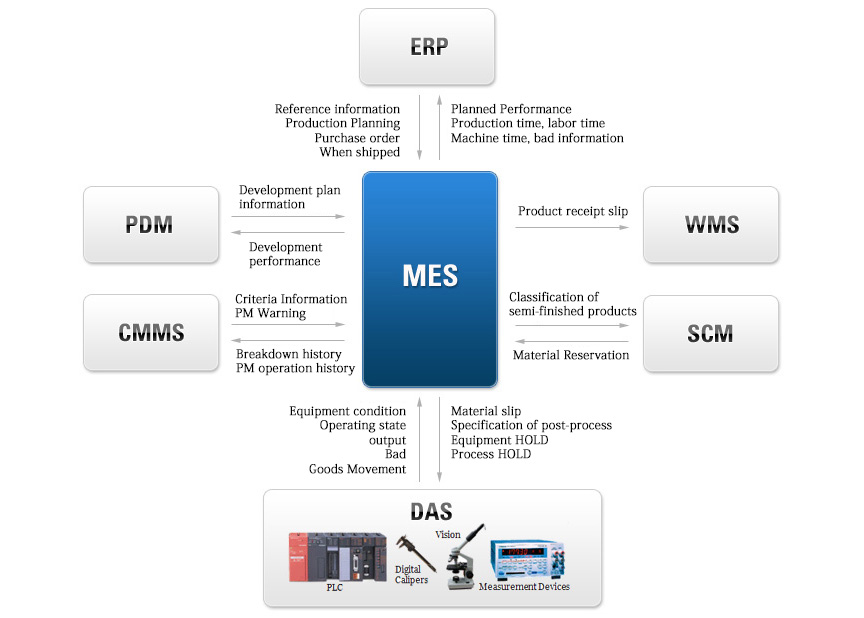

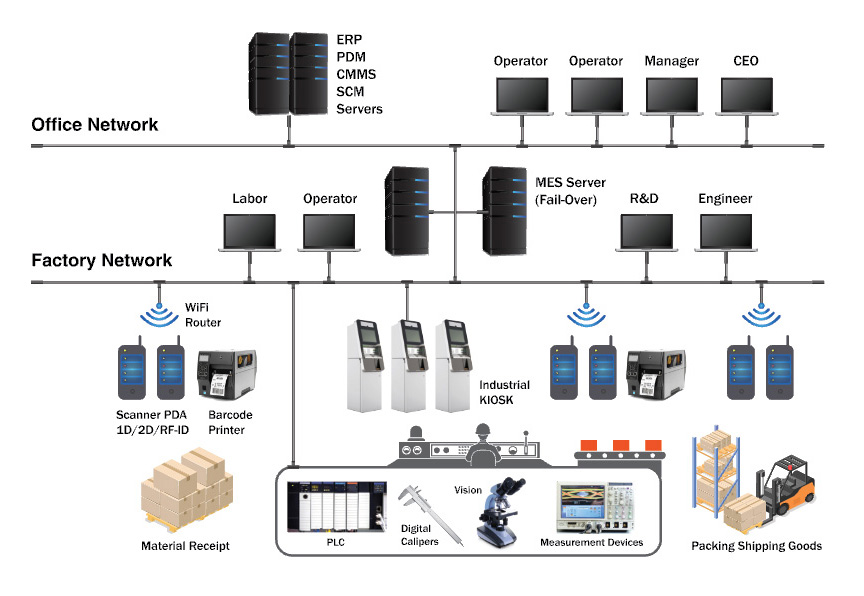

Schematic Diagram

Hardware configuration diagram

Key features: Interworking with ERP such as SAP and Oracle, monitoring real-time process status, checking real-time trends of major process parameters through Industrial KIOSK, data interlocking using barcode and RF-ID, real-time tracking of LOT Traceability System , Production, shipment, etc.)

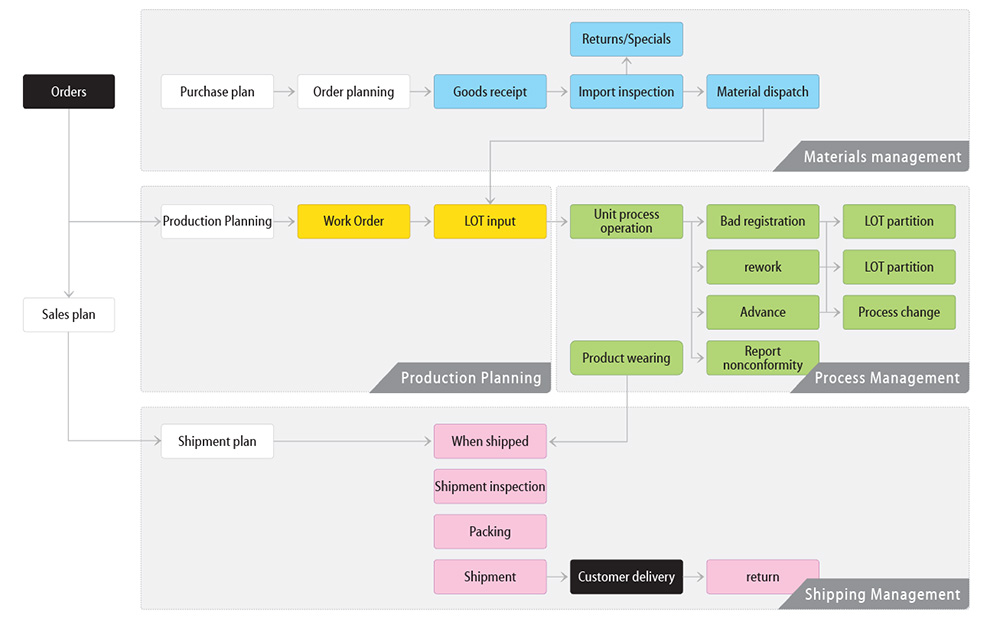

Process

Establish and distribute material supply and production plans according to sales plan and sales plan, and monitor movement of inter-process materials and work-in-progress. Real-time LOT tracking is also possible through defect management through quality control and overall flow control.

Software Configuration Diagram

FastMES has a stable structure, and other external modules are standardized together with individual service module in MES Core. Even if the production environment or manufacturing method is increased or changed, it is possible to respond quickly by setting environment and modifying MES

Base management

- Process code management

- Material / product code management

- Equipment Code Management

- Bad code management

- BOM management

- Parameter / Recipe Management

- Spec Management

- Source / Customer Management

- User / Operator Management

- System permissions management

- Code Master Management

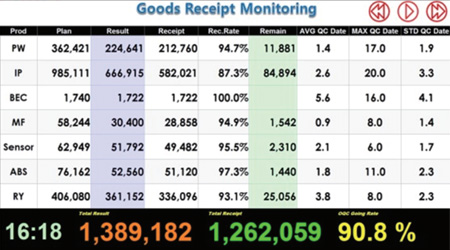

Materials management

- Material receipt

- Import inspection

- Returns / Specials

- Material dispatch

Production Planning

- Daily Production Planning

- LOT knitting

- Route lookup

- Material Inventory Status

- Planned Performance

Production Performance

- Status of work

- Total Production Status

- Input versus instructions / performance

- Production efficiency

- Production monitoring

- LOT Tracking

Process management

- Displaying work order

- Process Start / Complete

- Bad registration

- Process change

- Re-worker check

- LOT Tracking

- LOT split / merge

- HOLD / HOLD Release

- Report inappropriate / Inquiries

- Facility monitoring

Facility management

- Preventive maintenance management

- Mold & tool management

- Troubleshooting

- Availability Rate

- Non-moving status

- Facility efficiency

Quality Management

- Defect status

- Parameter analysis

- Yield status

Tracking management

- LOT tracking management (static deployment)

- LOT tracking management (reverse deployment)

- Bad Tracking Management

- Manufacturing history tracking management

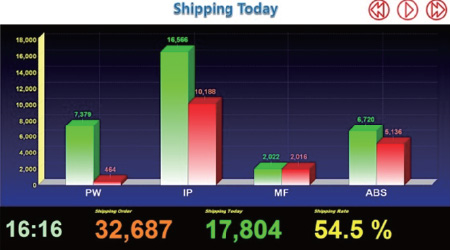

Shipping Management

- Goods Receipt

- Shipment instruction

- Shipment inspection

- Packing

- Shipment

- return

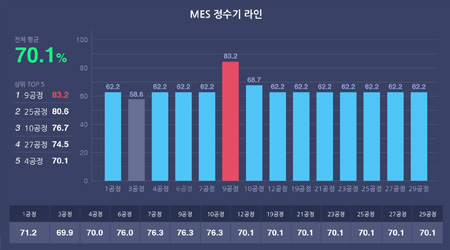

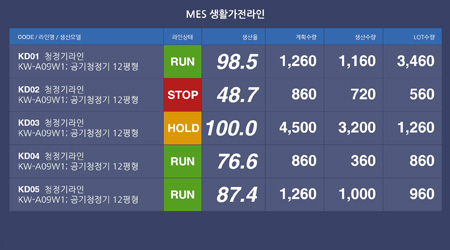

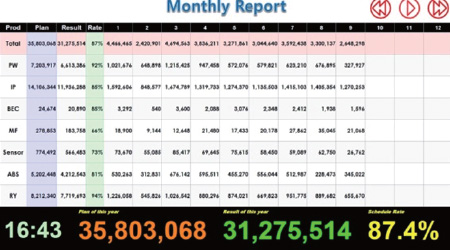

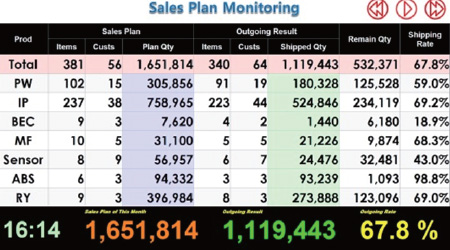

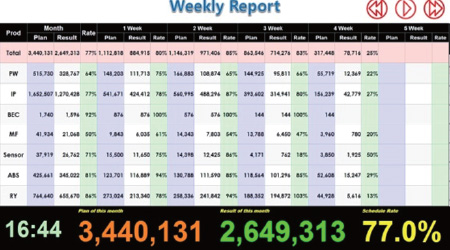

Main Screen

Effect of introduction

Improved real-time processing

Shorten work input time

Improved ability to respond to PL law

Decrease in paperwork

Lead time reduction

Decrease inventory hold

Operational effects

- Reduce lead time

- Improved real-time processing

- Increase worker productivity

- Reduced total production time

- Shorten work input time

- Improved ability to respond to PL law

- Reduced inventory

- Standardize work

- Product quality improvement

- Decrease in paperwork

- Decision Support

Business Effect

- Product Productivity Improvement

- Improving product reliability

- Quality improvement

- Improve customer service

- Improving ROI through IT Automation

- Asset growth

- Decision Support

- Reduced inventory cost

- Directive and transition agreement

- Operation cost and cost reduction

- Decrease financial expenditure

- Operation cost and cost reduction

Free One-Day Consulting

Are you currently reviewing the introduction of a new system or are you having difficulty implementing it? Please tell us without burden and we will contact you shortly.